Прочетете внимателно!

Technical product information

Transaction No.: 2012506/20

Vehicle judders when accelerating lightly; engine warning light sporadically on, entry P0403 - A4, A6 2.0l 4V TDI

Release date: 20-Sep-2013

Customer statement / workshop findings

a) The vehicle judders sporadically between 1400 and 2400 rpm when accelerating lightly. A brief knocking noise can occur during the juddering.

b) Engine warning light on, engine starts erratically, poor performance (emergency operation)

Sporadic entries:

P0403 exhaust gas recirculation valve malfunction

P0407 potentiometer for exhaust gas recirculation G212 – signal too small

P0408 potentiometer for exhaust gas recirculation G212 – signal too big

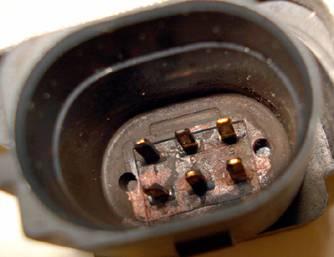

Plug and plug housing of exhaust gas recirculation valve damp:

In isolated cases the humidity can get to the engine control unit plug and cause pin corrosion:

Technical background

a) Software deviation of the engine control unit control to the exhaust gas recirculation valve.

b) Humidity ingress because of incorrect shaft seal of exhaust gas recirculation valve.

Production change

---

Measure

a)

Check and if necessary update the data version.

•

See also Argumentation.

Old engine control unit

New engine control unit

New data version

SVM code

CD part number

03G 906 016 GB

03G 906 016 GB

9886

M4ZSA001

4E0 906 961 AH

03G 997 012

03G 906 016 GB

9886

M4ZSAP001

4E0 906 961 AH

03G 906 016 HS

03G 906 016 HS

9908

4F01A029

4E0 906 961 AH

03G 906 016 HQ

03G 906 016 HQ

9909

4F01A029

4E0 906 961 AH

03G 906 016 ME

03G 906 016 ME

1141

M4ZSA001

4E0 906 961 AH

03G 906 016 MF

03G 906 016 MF

1142

M4ZSA001

4E0 906 961 AH

03G 906 016 MG

03G 906 016 MG

1143

4F01A028

420 906 961 B

03G 906 016 MH

03G 906 016 MH

1144

4F01A028

4E0 906 961 AH

03G 906 016 BF

03G 906 016 BF

9970

4F01A043

8T0 906 961 L

03G 906 016 GG

03G 906 016 GG

9552

4F01A014

4L0 906 961 A

03G 906 016 GC

03G 906 016 GC

9887

M4ZSA001

4E0 906 961 AH

03G 997 056 T

03G 906 016 JD

03G 906 016 JD

9905

8E01A036

4E0 906 961 AH

03G 906 016 JB

03G 906 016 JB

9906

8E01A036

4E0 906 961 AH

03G 906 016 GN

03G 906 016 GN

9880

8E01A032

4E0 906 961 AH

03G 906 016 FC

03G 906 016 FC

9621

8E01A011

8E0 906 961 N

03G 906 016 LR

03G 906 016 LR

1838

8E01A036

4E0 906 961 AH

03G 906 016 JE

03G 906 016 JC

03G 906 016 JC

9907

8E01A036

4E0 906 961 AH

03G 906 016 CL

03G 906 016 CL

9881

8E01A032

4E0 906 961 AH

03G 906 016 FD

03G 906 016 FD

9620

8E01A011

8E0 906 961 N

•

An update with CD via self-diagnosis is not possible. If the tester cannot find the files for the update, insert the CD (see table) and perform the update as described above with the SVM code.

•

If this also not possible, contact your IT support.

•

Note: In future the Audi AG will not use CDs any more, so the an update is only possible with SVM.

After the software update programme the exhaust gas recirculation valve as follows:

1. Disconnect battery charger and switch off ignition. The battery voltage must be between 10 - 14 V (see under engine electronics - measured value block 12 - value 3). The coolant temperature (engine temperature) must be over 5°C (see under engine electronics - measured value block 1 - value 4)

2. Switch on the ignition and within one to three seconds off again.

3. The ignition must be off for at least 45 seconds.

4. Switch on the ignition again and check the offset programmed value under engine electronics - measured values - measured value block 42 - value 1: With 0 km vehicles the value is around -16 % +-3 . For every 10000 km the offset programmed value moves about 1% towards 0. Example: running period 40000 km = -12 % +-3 % or 80000 km = -8 % +-3 %. But these are not definite figures, as the running period of the vehicle can differ from that of the component (for example if the exhaust gas recirculation valve was replaced).

The process described under 1, 2 and 3 may have to be repeated up to 10 times.

•

The entry - P0403 exhaust gas recirculation valve malfunction - is logged after the update or during the test drive (after about 500 m). The entry does not mean that the exhaust gas recirculation valve is incorrect, but that the programming has not been correctly completed. Repeat the process described under 1, 2 and 3.

Sometimes the entry - P0403 valve for exhaust gas recirculation malfunction- cannot be deleted even after programming it 10 times. If this is the case, replace the valve for exhaust gas recirculation. A programming of the exhaust gas recirculation valve is necessary after the replacement.

If after the update the vehicle still judders sporadically when accelerating lightly, proceed as follows:

- Check the air hoses after the air mass meter for leaks

- Check the boost pressure pipes for oil marks, cutting lines, cracks or damage through animal bites. Pressurise the complete boost pressure pipes with V.A.G 1687 according to repair manual (max. 0.5 bar).

If the judder still occurs on the A6 with 2.0 l TDI, fit the seal with part number 028 131 547 B between exhaust gas recirculation cooler and pipe.

b)

Check the plug and pins of the exhaust gas recirculation valve for humidity or corrosion:

If corrosion or traces of dampness are detected, replace the exhaust gas recirculation valve according to the parts catalogue. If there is humidity or corrosion in the 60 pin engine control unit plug, replace the engine control unit and fit the adapter wiring loom as follows:

Prepare adapter wiring loom:

Wrap insulation tape around the cable ends to protect the contacts and to make the feeding through the grommet easier (illustration).

A4 (B7) LHD:

Route the adapter wiring loom following the red line.

Overview:

Mounting points:

1) Place the adapter wiring loom in the existing cable holder.

2) Attach the adapter wiring loom with a cable binder on the engine wiring loom.

Feeding-through of grommet:

1) Use the existing opening of the grommet for the feeding-through into the E-box. Seal off the space between the cables with butyl.

To complete the process proceed in the 60 pin engine control unit plug according to the current flow diagram.

A4 (B7) RHD:

Route the adapter wiring loom following the red line.

Overview:

Mounting points:

Attach the adapter wiring loom on the two marked places with cable binders.

Feeding-through of grommet:

Use the grommet of the battery cable for the feeding-through into the plenum chamber.

To complete the process proceed in the 60 pin engine control unit plug according to the current flow diagram.

With engine code BRD and BVA:

Connect the two other cables (without attached contact) according to the current flow diagram with the two cables of boost pressure regulator (use crimp connector). The crimps are still in the E-box. Remove the tape of the engine wiring loom in the E-box.

A6 (C6) LHD

Route the adapter wiring loom following the red line.

Overview:

Feeding-through of grommet:

Remove the blanking plug and fit the grommet of the wiring loom for the feeding-through into the plenum chamber.

E-box feeding-through:

Feed the adapter wiring loom on the marked place into the E-box.

To complete the process proceed in the 60 pin engine control unit plug according to the current flow diagram.

A6 (C6) RHD

The routing to the plenum chamber is identical with the LHD, but in the plenum chamber it must be the other way round.

Warranty accounting instructions

Service number/damage code/manufacturer: 2360 /0039/... (engine control unit update)

Service number/damage code/manufacturer: 2647/0012/… (installation of seal)

Service number/damage code/manufacturer: 9752/0033/… (plug/pins corroded)

a)

Accounting with APOS:

Software update:

Repair operation:

Designation:

Time units:

27 06 89 50

Charge battery

10 TU

01 50 00 00

GFF/guided functions

TU according to diagnosis protocol

Check boost air system:

Repair operation:

Designation:

Time units:

21 41 01 99

Check boost air system

30 TU

Replace exhaust gas recirculation valve:

Repair operation:

Designation:

Time units:

26 39 19 39

Remove and install exhaust gas recirculation valve

70 TU

Remove and install EGR cooler seal

Repair operation:

Designation:

Time units:

26 43 19 99

Remove and install EGR cooler seal

70 TU

Accounting with APOS/2:

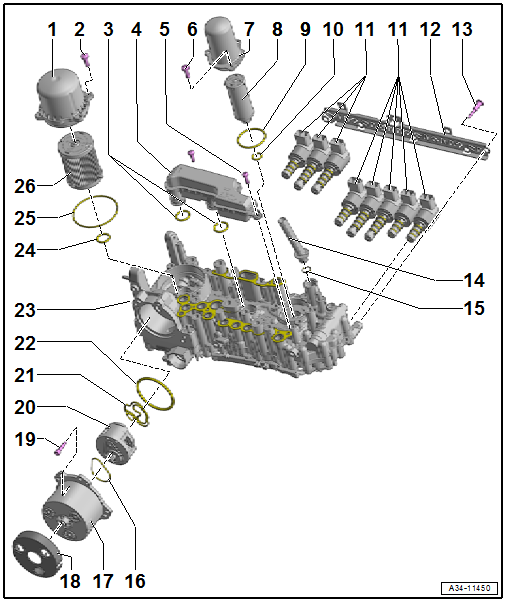

Illustration:

Position:

Number:

Designation:

Activity:

Time units:

STA-02

4

915105

Charge battery

90

10 TU

STA-02

1

S00032

Guided fault finding (Software update)

02

TU according to diagnosis protocol

145-xx

x

145737/145738

Check boost air system

98

30 TU

131-xx

x

131501

Replace exhaust gas recirculation valve

55

According to instructions

131-xx

x

131547

Replace EGR cooler seal

55

According to instructions

b) Account according to time used and include operations of APOS and APOS/2.

Parts information

Adapter cable part number (for RHD and LHD):

4F0 971 379 A Audi A4 2,0l 4V TDI 100/103KW

4F0 971 379 B Audi A4 2,0l 4V TDI 120/125KW – engine code: BRD and BVA

4F0 971 379 C Audi A6 2,0l 4VTDI 100/103 KW

The adapter cables are not in included in the parts catalogue.

Customer information

•

The new software includes an improvement of the clutch protection function, as a result the starting characteristics change. The accelerator pedal has been changed so that with the same part load accelerator position less fuel is injected. This leads to a slightly worse acceleration, but the driver can compensate this, for example by pressing the accelerator pedal press pedal further. The injected fuel quantity with full load has not been changed.